‘Every wood has a story’

Everything starts from the moment our customers share their needs and aesthetics. With our experience in interior architecture, we give our suggestions. Our samples are the ones that determine the selection of wood or live edge slab and then comes the preparation of technical drawings or even a three-dimensional model, which is the basis for the beginning of the creation of the furniture.

If wood selection is not in stock, it is located in the pre-agreed dimensions, cut and treated-sterilized in our kiln-oven.

From the moment a piece of solid wood is cut from its trunk, it continues to breathe. Each live edge slab depending on the wood type, more often than not contains humidity, tar, insects and other living organisms. For this reason, a specific long treatment is needed in order to assure a clean and dry piece of furniture.

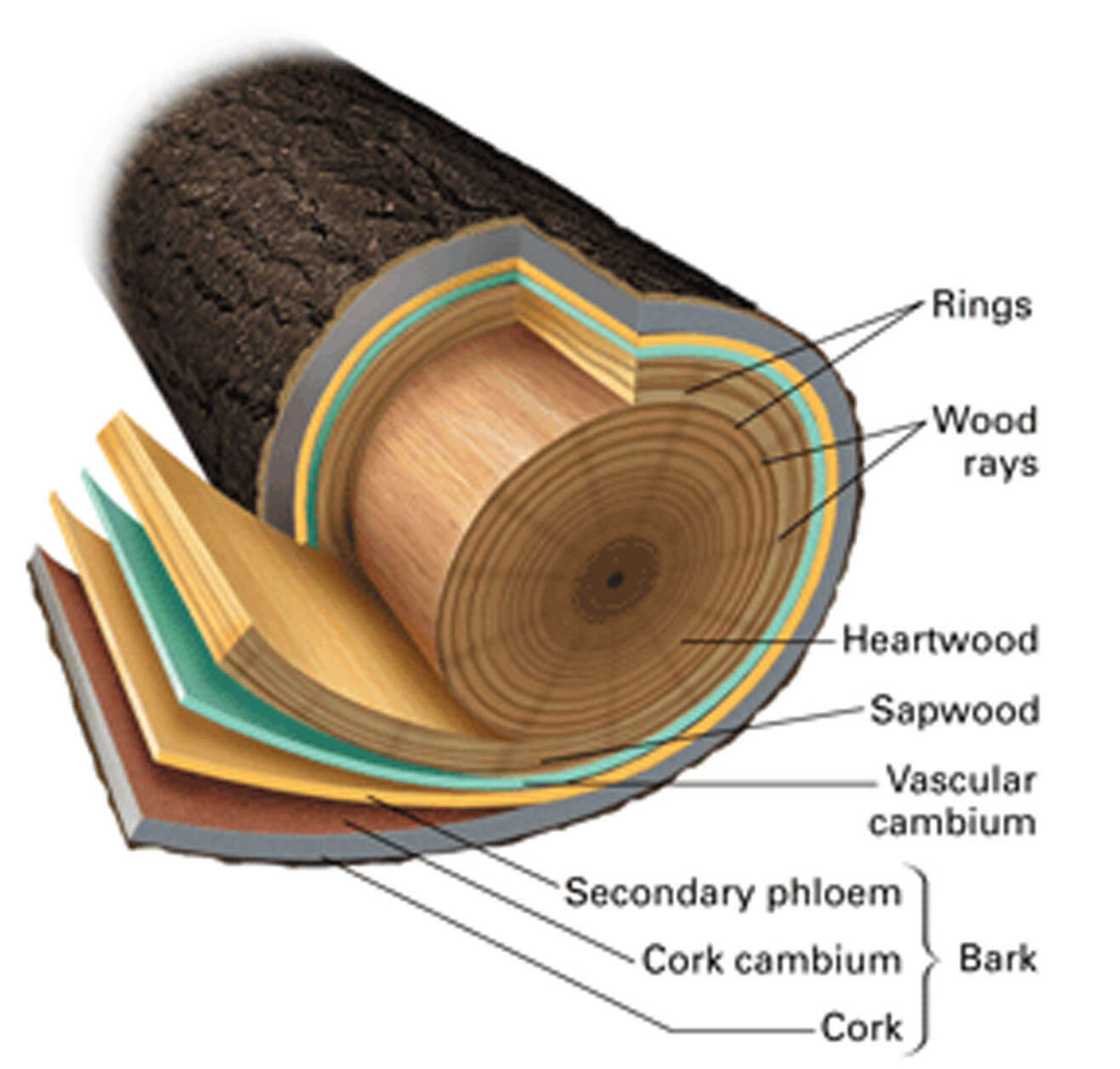

The wood contains numerous layers of bark, wood rays and rings. The obvious layers need to be peeled off, a time-consuming, long and handmade procedure which requires mastery, time and patience.

The next important step has to do with placing the wood inside the kiln to start the slow heat treatment which will destroy any possible living organisms, melt and remove the tar, and finally dry it from the water it may contain inside its core. Therefore a specialized wax is being added at the wood edges first, which will prevent cracks from being created or becoming larger during the heat treatment, as the wood contracts. Once the wax is dry, the wood is being placed inside our professional oven. The humiditor measures the humidity prior to placing it inside the kiln.

The process of heat treatment in the kiln is a procedure which needs to be checked several times during, and is vital to be made slowly. The element inside the oven generates and sustains heat according to the outside temperature. Upon the completion of this operation, the element switches off. Finally, the kiln doors open and the freshly treated pieces of natural wood are ready to head to the carpenter, who will cut, plane and sand to achieve a smooth result.

The technical drawings of the furniture to be created, which were already confirmed by the client, move on to the hands of the carpenters, the metal workers, to the varnish and to other technicians involved.

While our furniture is in the making at the carpenter and while they move on to other technicians, the supervision by Euphoria team is substantial.

Unforeseen obstacles may occur which are always solved

on the spot with the team’s knowledge.

The beauty and love for our work lies at what is for us the greatest value:

the manufacturing process which is equally important

as the result of a piece of furniture.

The process unfolds all the potentials and the result

is where the efforts take shape.

The furniture gains the form we envisioned and in conclusion,

it is delivered to the customer.

Euphoria furniture Founder